Takasho Original Brands & Materials

More information on decors, panels, cross-sections and dimensions – take a closer look at our materials.

All our materials and products are manufactured according to four aspects:

EXPRESSION

The modern embossing and manufacturing processes enable an authentic and beautiful surface finish. Elaborate reproduction convinces with its realistic appearance. Thanks to the three-dimensional shapes, beautiful subtle shadows and a surface close to nature are created.

TRUE TO ORIGINAL COLOURS

A diverse colour selection offers a faithful reproduction of different materials for every taste. The different brightness levels and nuances match any exterior and create a uniform look. The textured surface creates realistic plays of light and shadow.

DURABILITY

40 years of valuable experience characterise our products and work. A high resistance of the products enables a long service life, protection against environmental influences and weather as well as enormous reliability in use. We guarantee the highest quality of our products and give a 10-year warranty on all surfaces.

EASY HANDLING

The Products are easy to handle and can be applied nearly anywhere. Both indoors and outdoors, they inspire with their functionality and appearance. The high-quality materials are suitable for new buildings and existing properties.

USPS

Superior Japanese Quality Standards

As the pioneer of total exterior manufacturing and as a creator of garden lifestyles, our focus is on connecting people with nature by promoting the next generation of peaceful, lifestyle and outdoor garden environments.

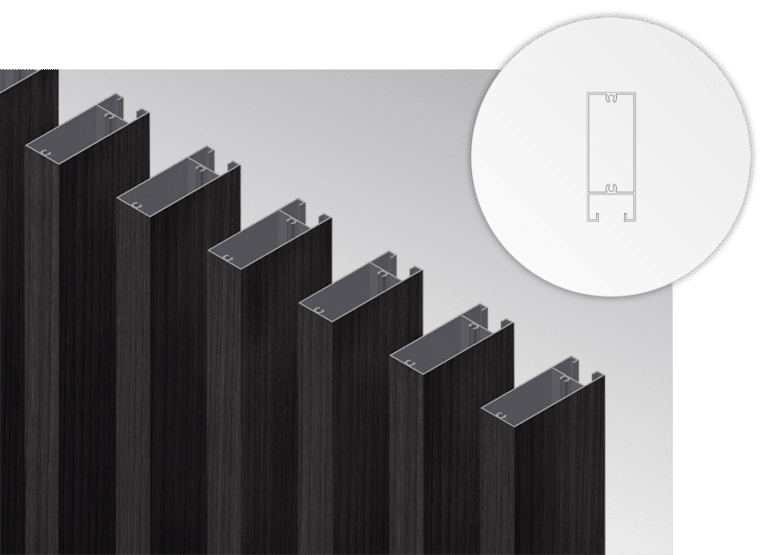

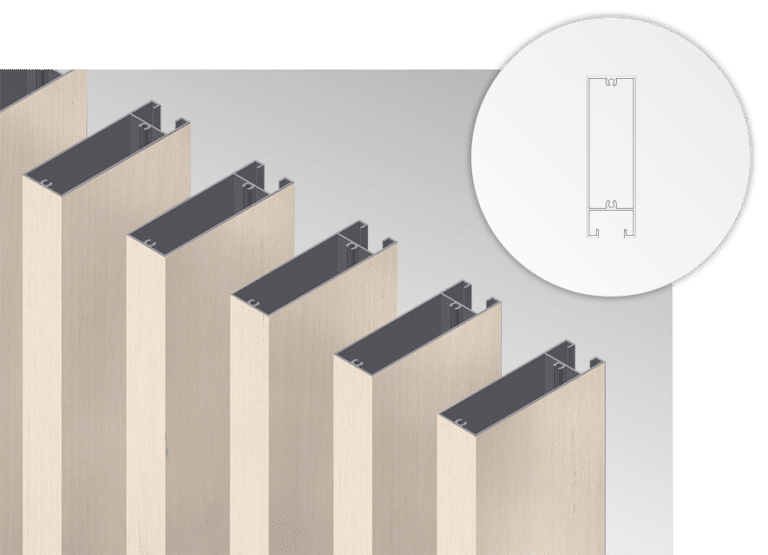

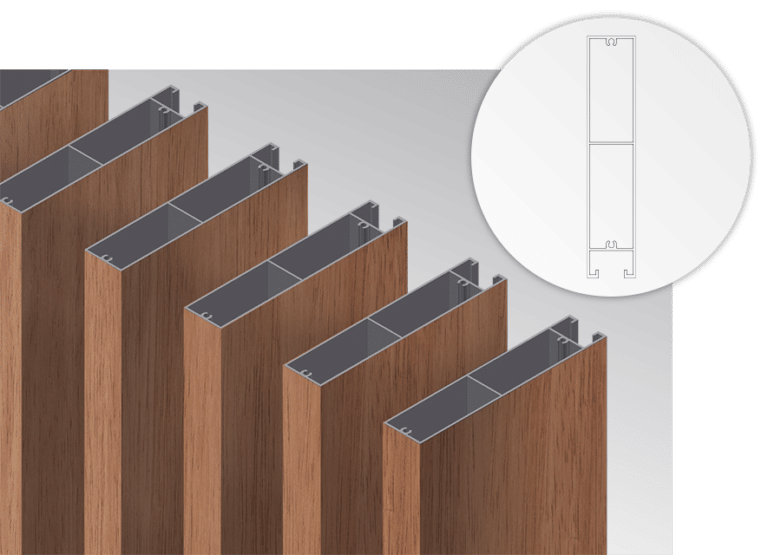

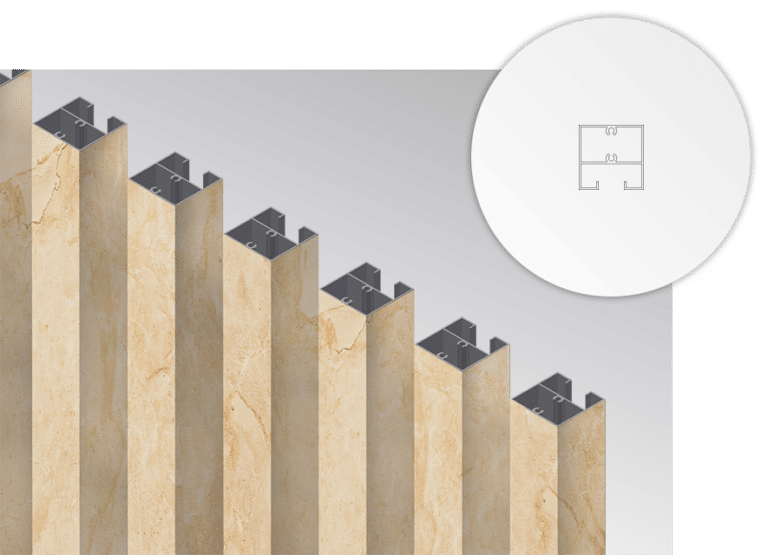

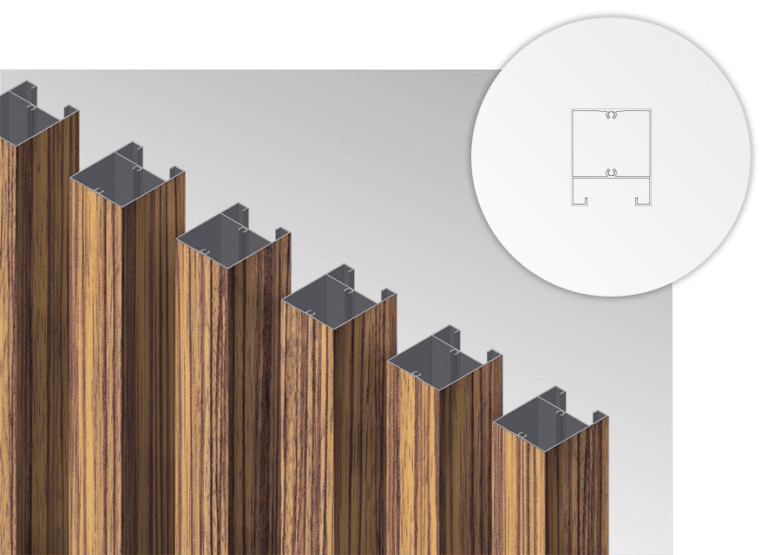

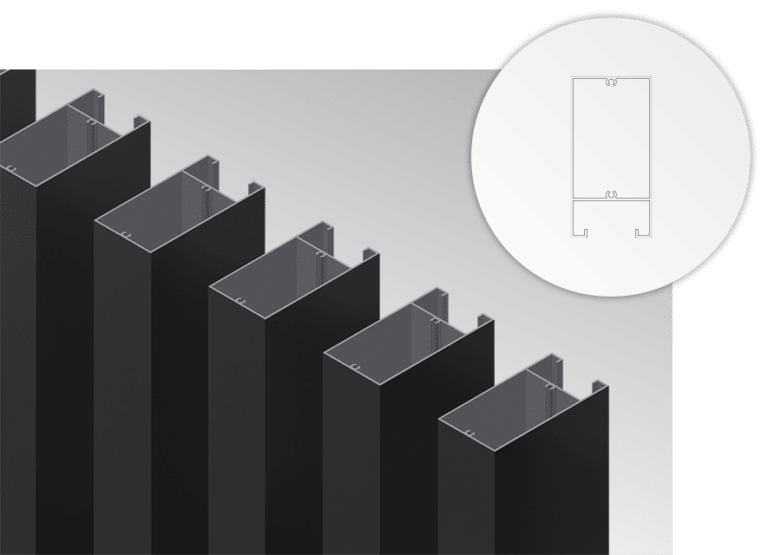

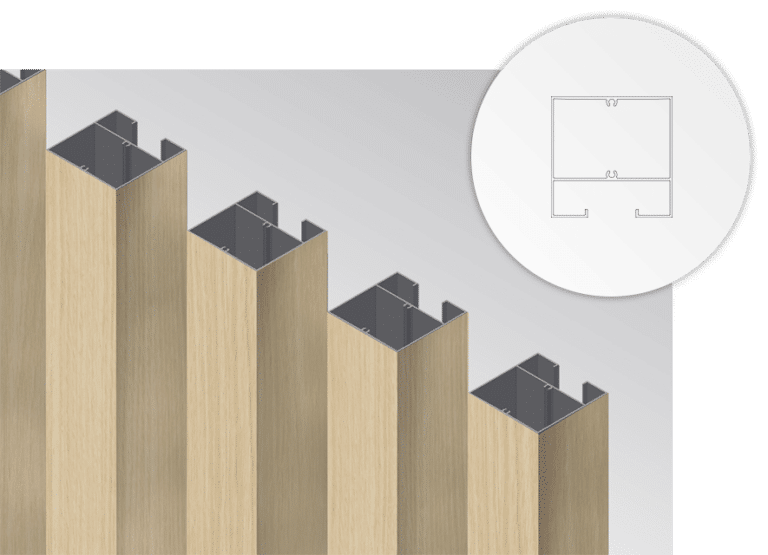

TAKASHO PROFILE SERIES

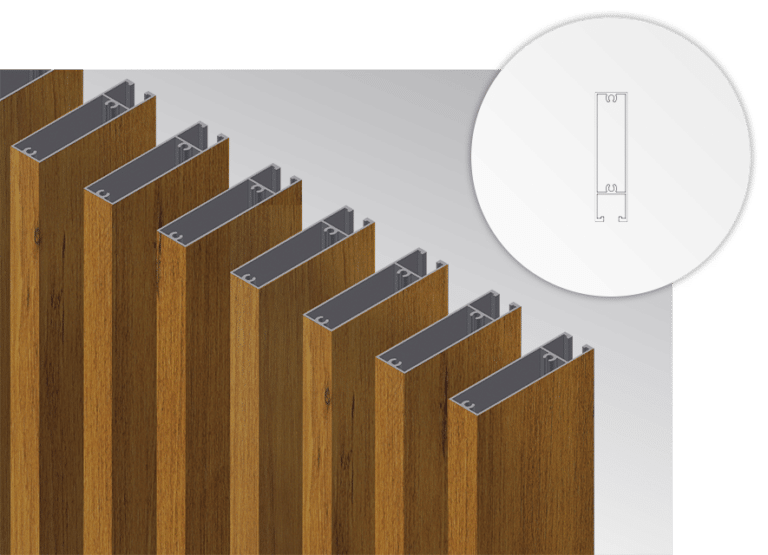

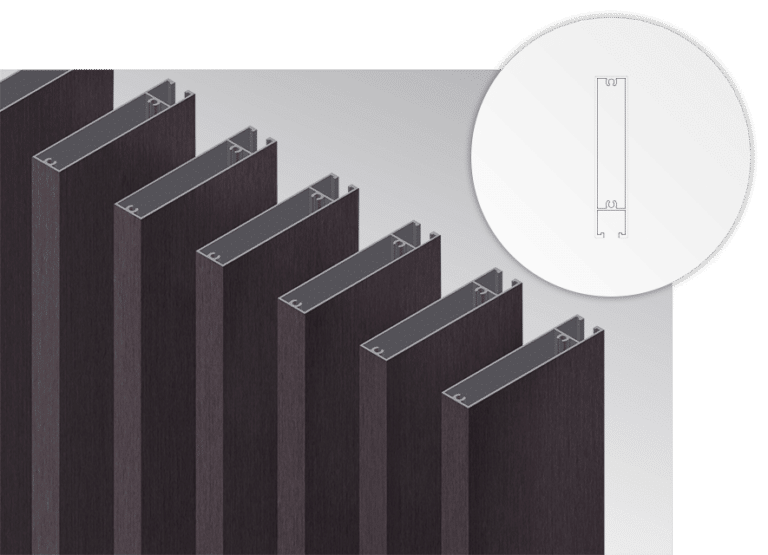

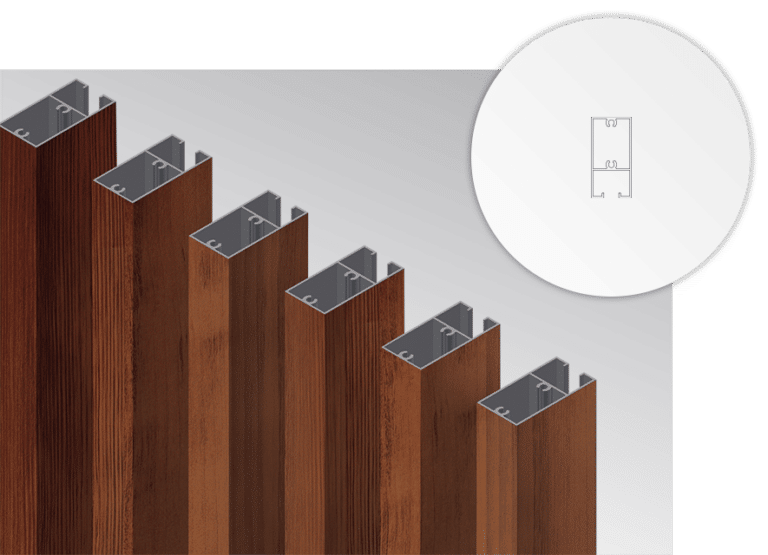

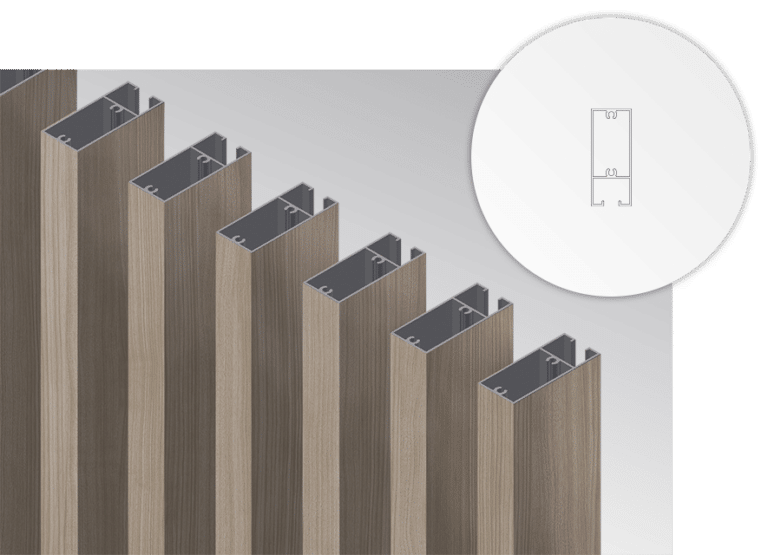

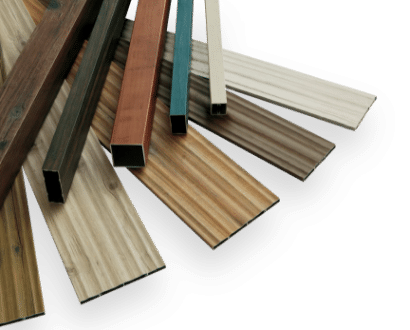

EVER ART WOOD®

High quality laminated aluminium profiles.

ALUMINIUM FENCING, BATTEN CLADDING - UNIVERSAL STANDARD PROFILES

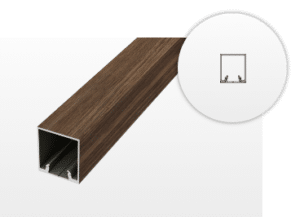

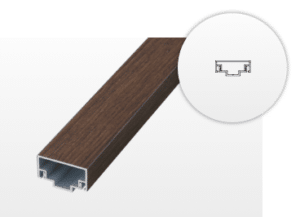

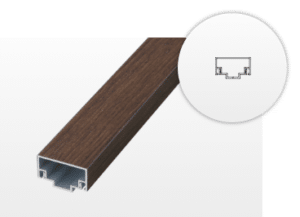

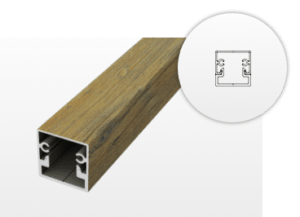

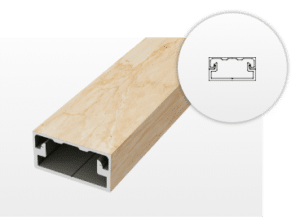

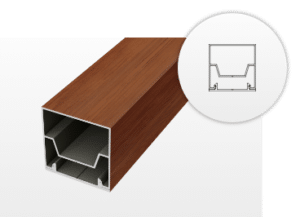

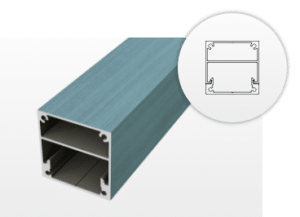

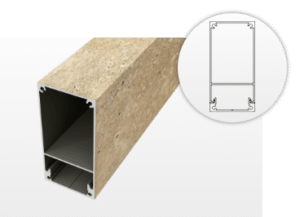

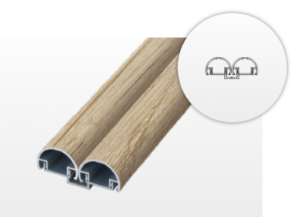

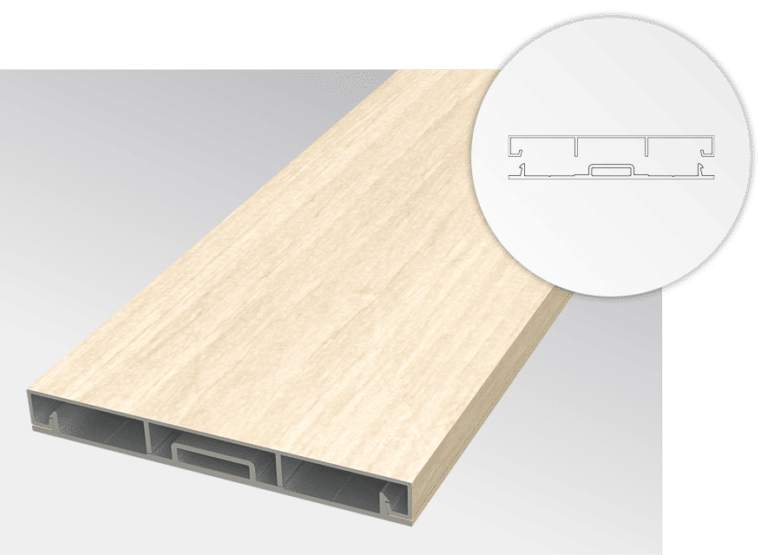

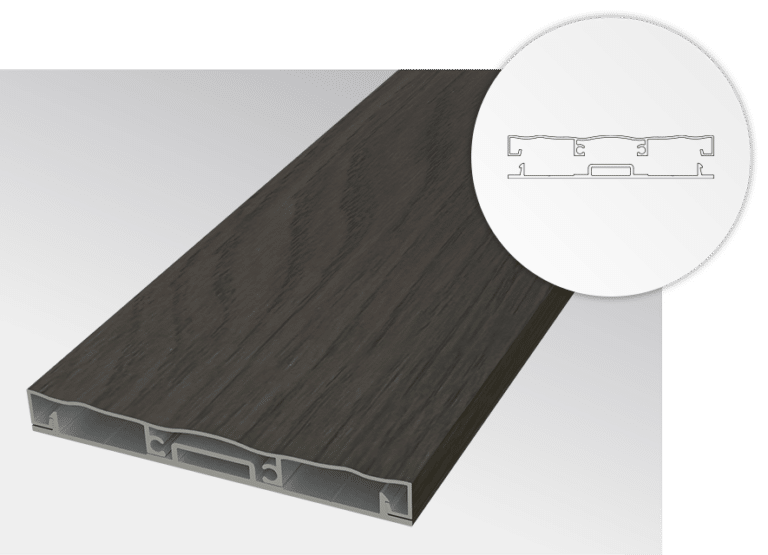

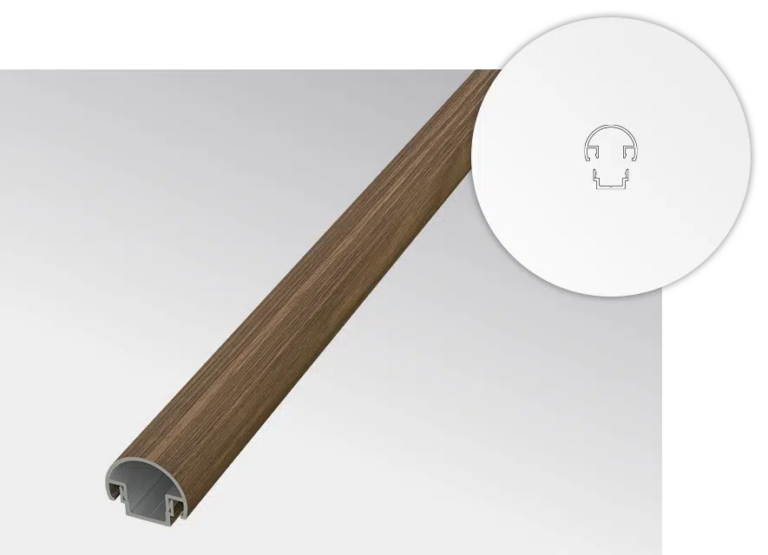

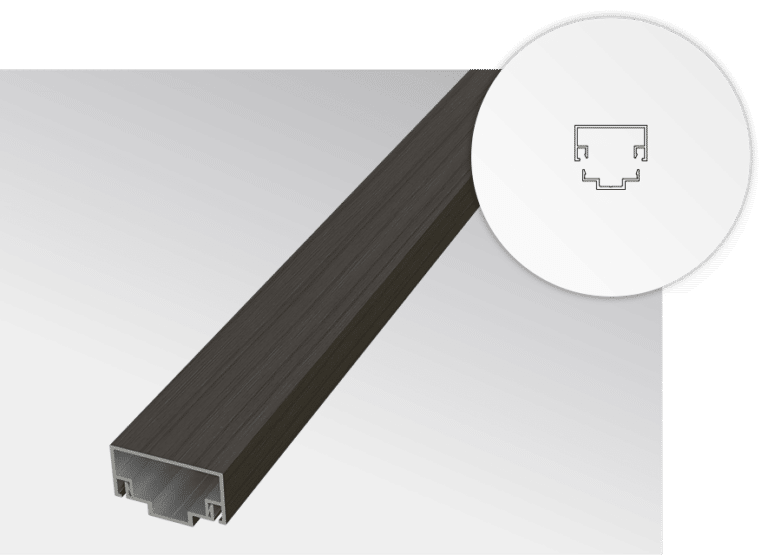

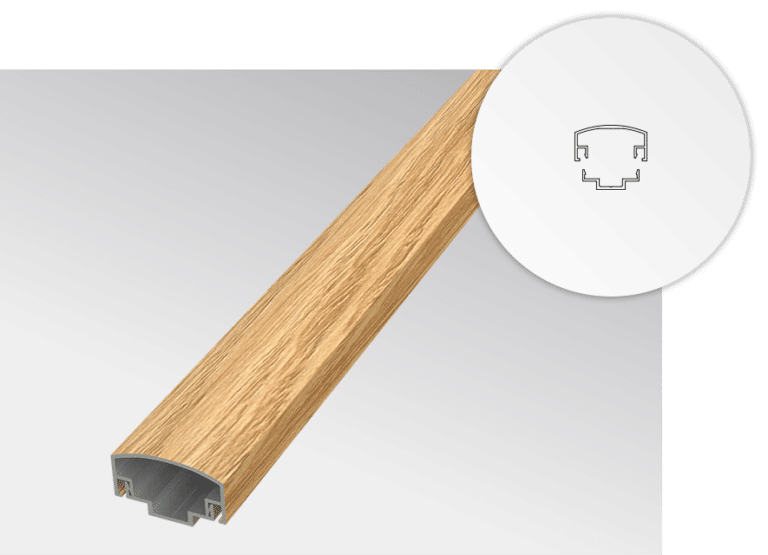

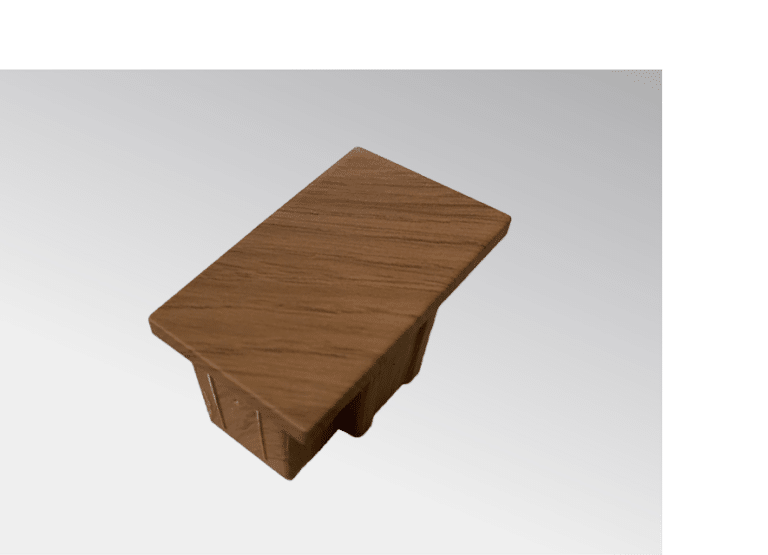

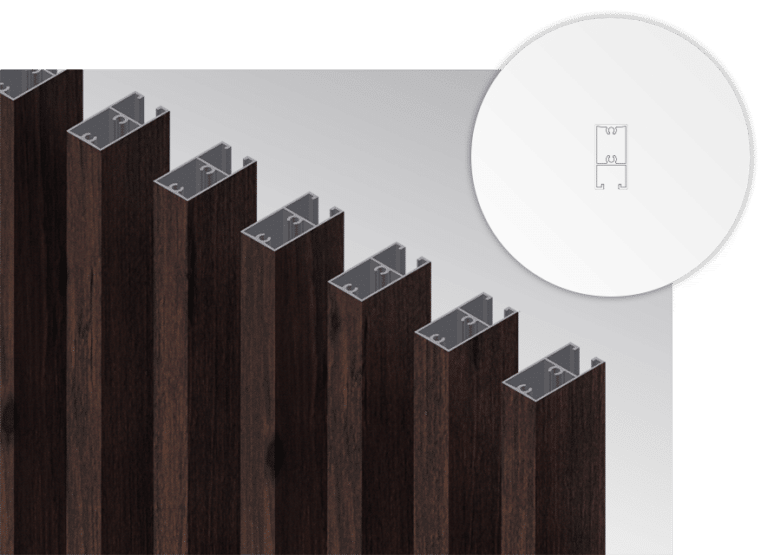

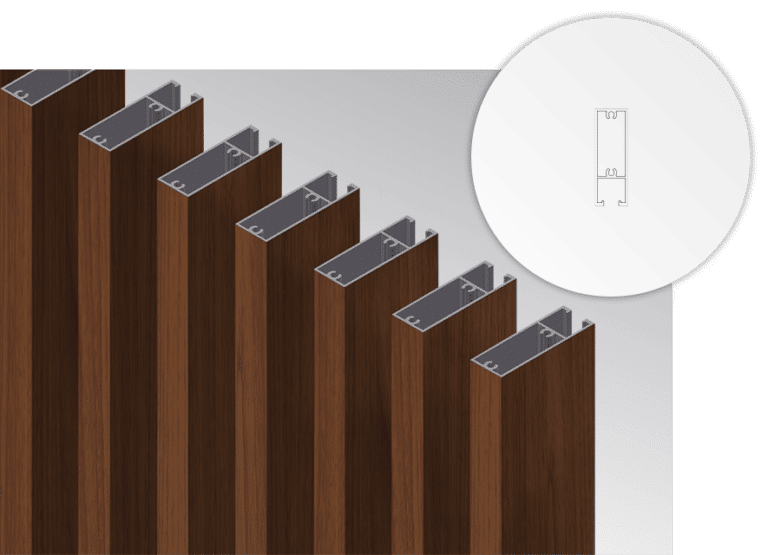

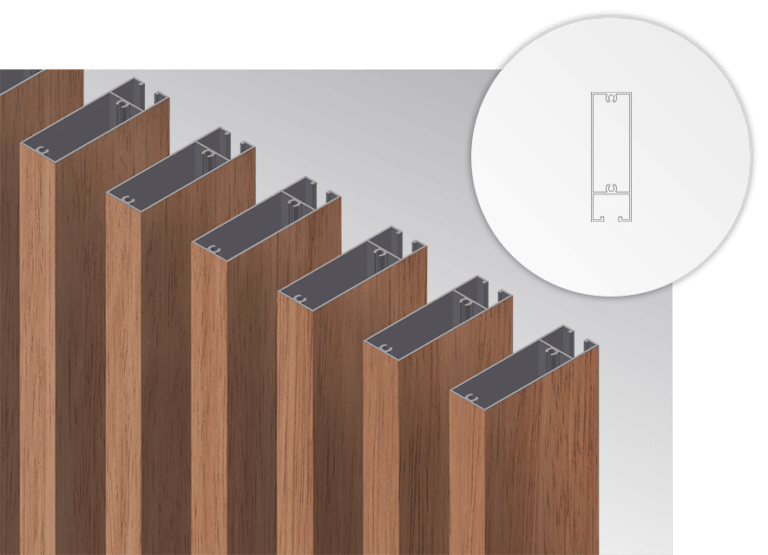

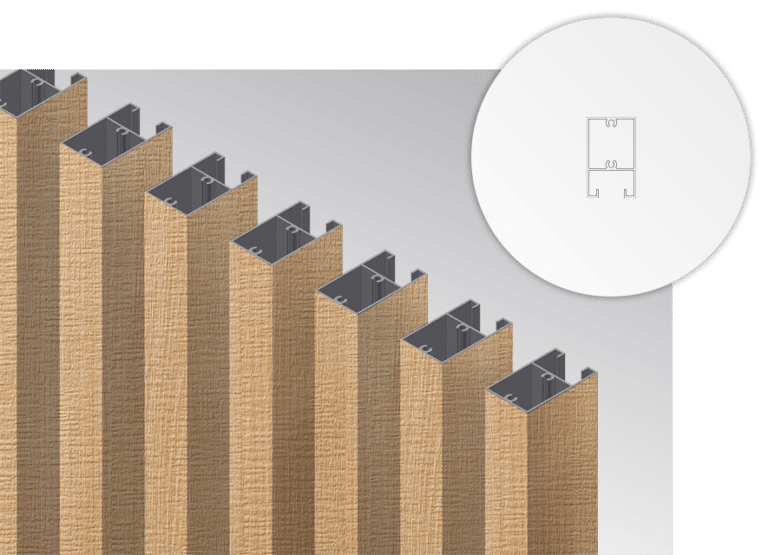

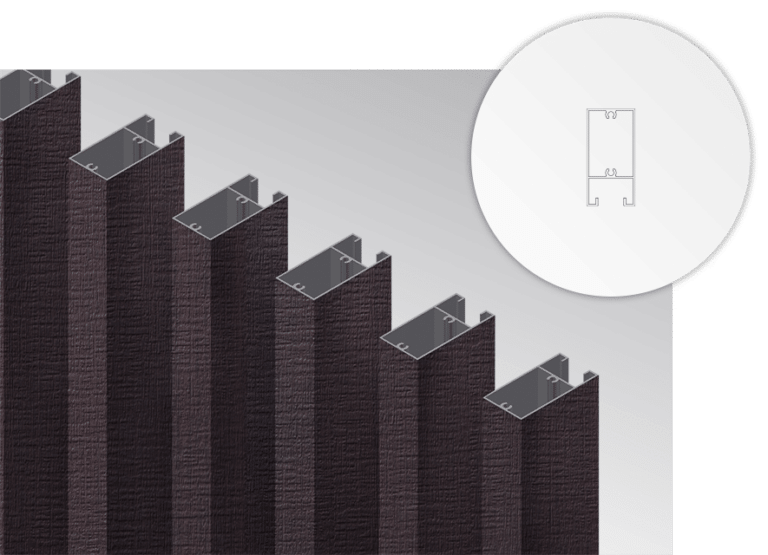

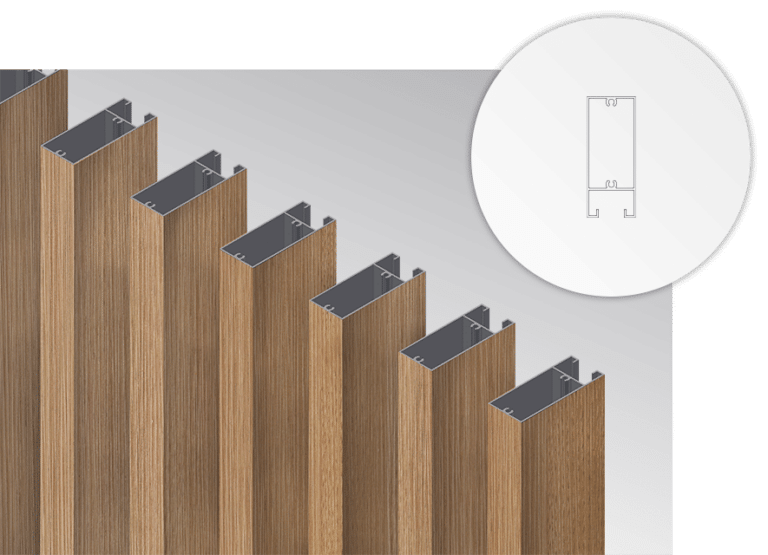

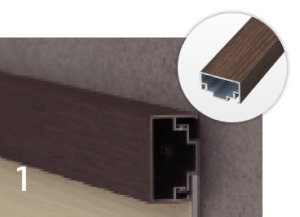

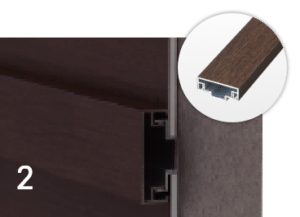

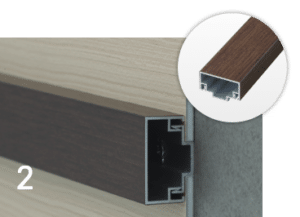

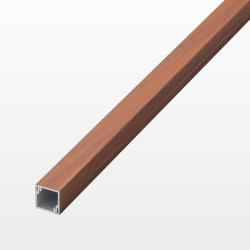

Battens and Louvres

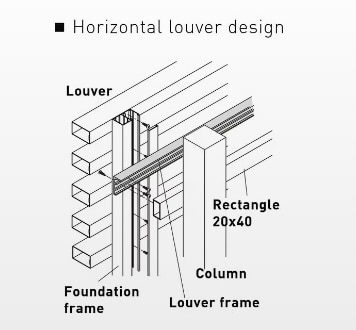

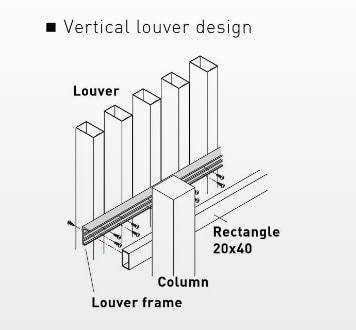

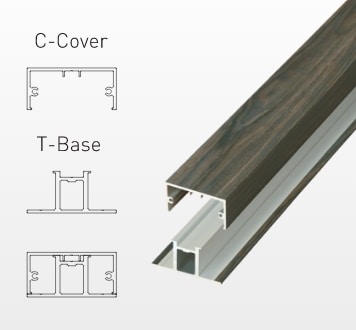

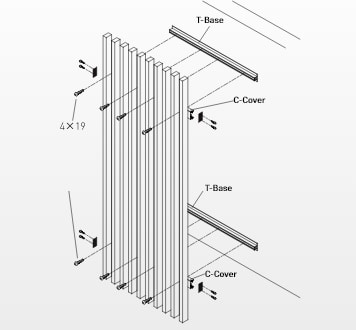

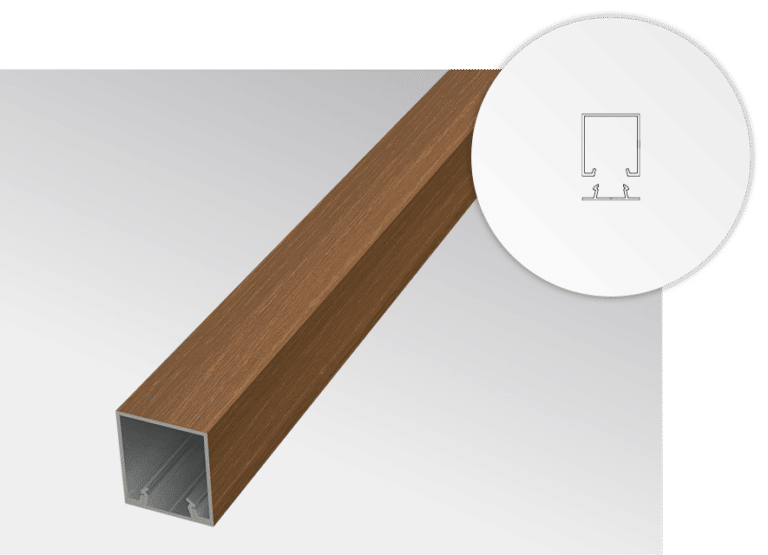

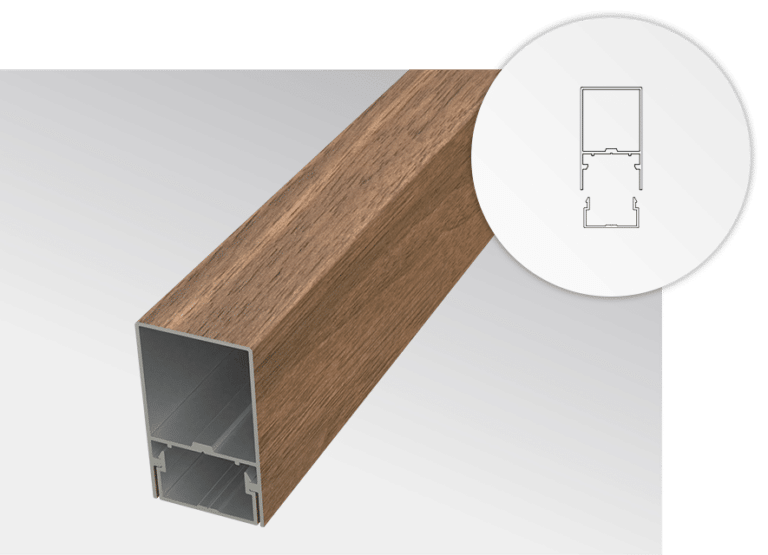

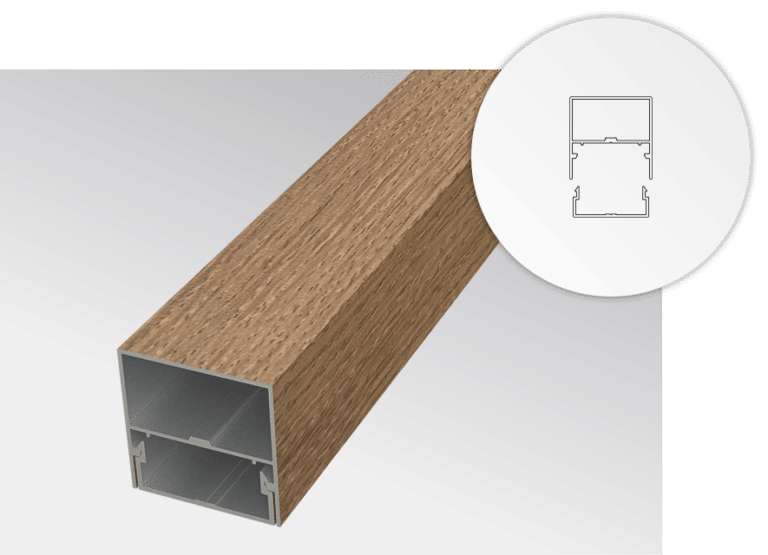

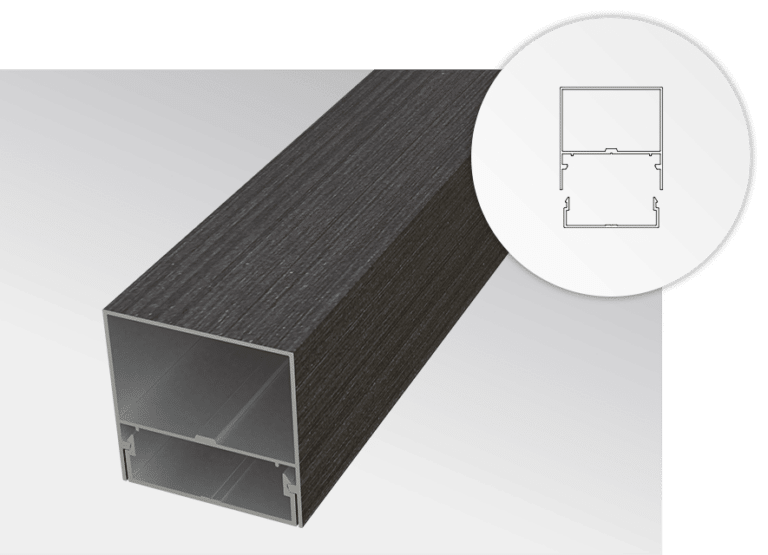

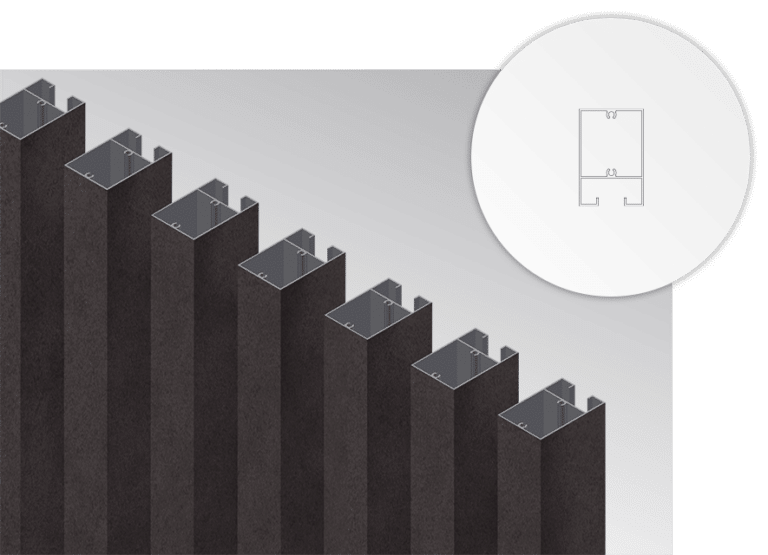

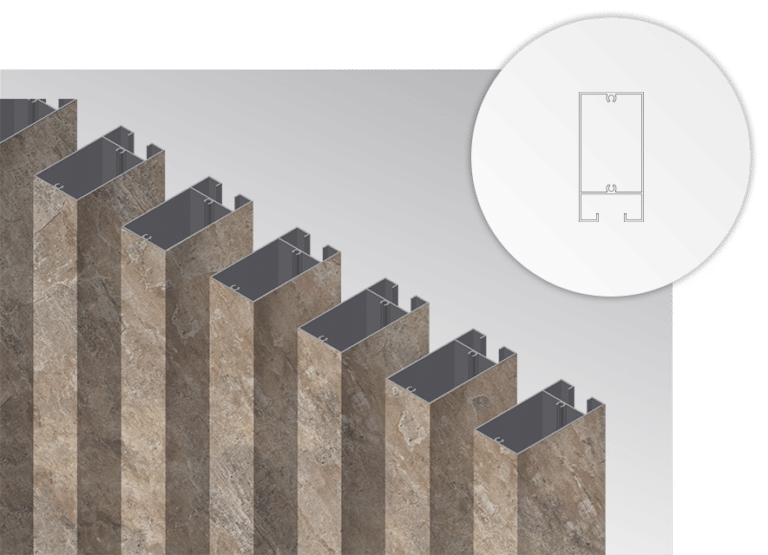

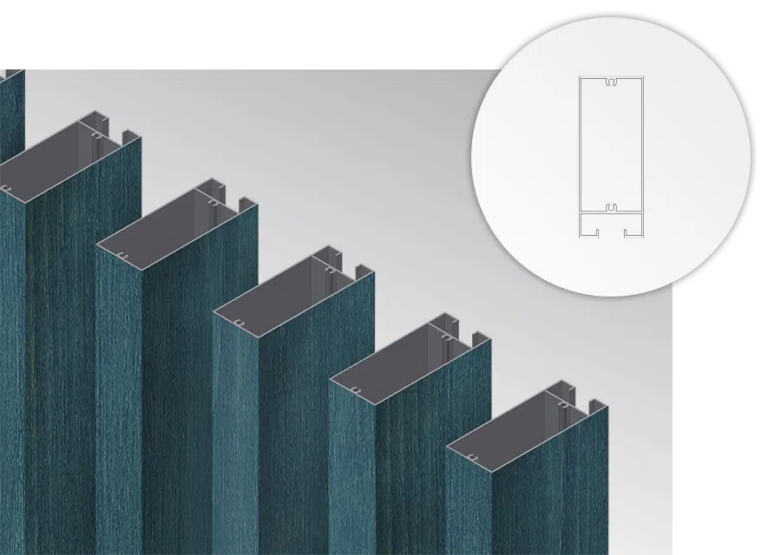

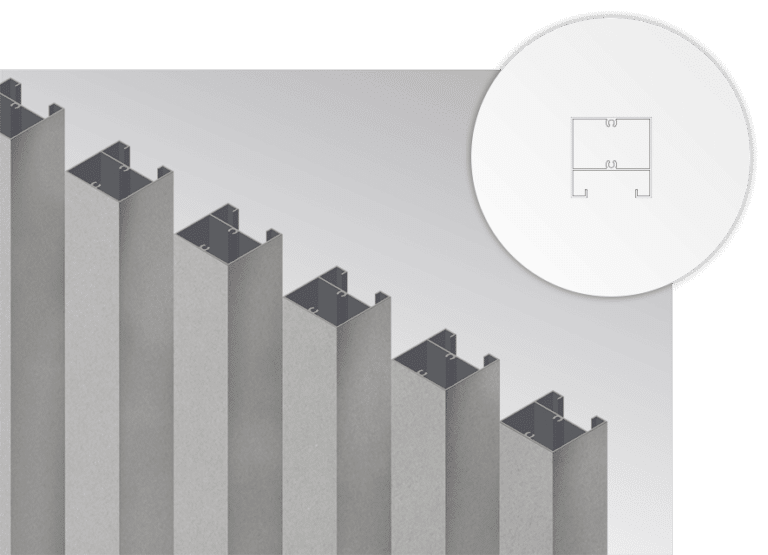

Our louvres not only convince with different designs, but also with a variety of different profile types. Square, rectangular or rounded – you are sure to find the right profile type for your needs. The louvers have profile sizes that are matched to the requirements, have a low dead weight and can be easily processed into a Louvre system.

The thickness of the profile affects the sound insulation as well as thermal values and should therefore be chosen carefully. We also offer profiles with modern lighting solutions, in the form of columns as well as with attractive foundation frames.

BASIC INSTALLATION METHODS - UNIVERSAL STANDARD PROFILES

Foundation Frames for Aluminium Louvres

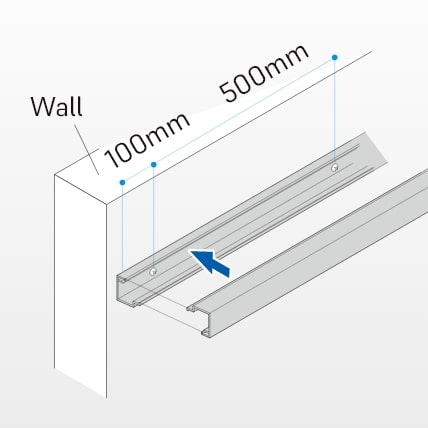

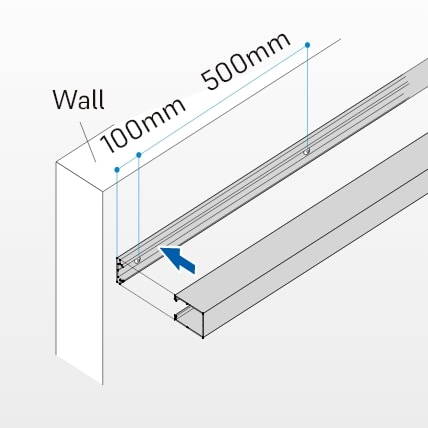

BATTEN CLADDING - C-SYSTEM

C-System - Easy Clicksystem

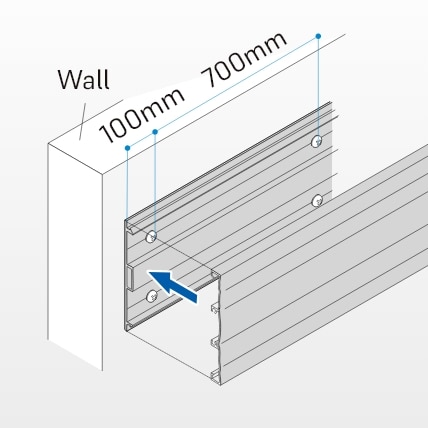

BATTEN CLADDING - U-SYSTEM

U-System - Precisely prefabricated, precisely aligned on site

Sponge plugs to assist with fixing during alignment

Retaining clip for smaller profiles

Retaining clip for large profiles

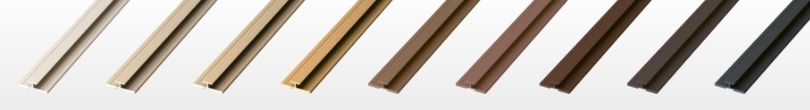

PROFILES - COLOURS AND DECORS

66 Design Options with EVER ART WOOD®

* = NATURAL TOUCH (EMBOSSING TEXTURE)

TAKASHO ALUMINIUM COMPOSITE BOARD SERIES

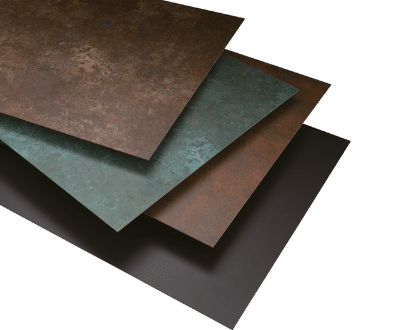

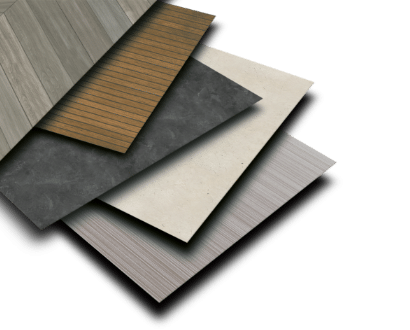

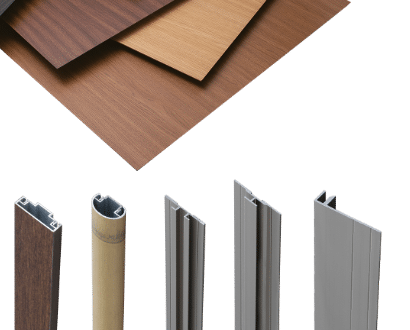

EVER ART BOARD®

Expressive laminated aluminium composite board.

WALL CLADDING - ALUMINIUM COMPOSITE BOARD

Natural Look & Work-oriented specifications

Aluminium composite panels are light and easy to handle on the construction site. This speeds up work processes and saves valuable construction time. The easy handling as well as the stability and reliability of the panels also enable smooth transport and effortless assembly on site

Aluminium composite panels

| B×H | 910 × 1820 mm |

|---|---|

| T | 3.0 mm |

| kg | 4.0 kg |

Aluminium composite panels

| 910 × 2440 mm |

| 3.0 mm |

| 5.4 kg |

Aluminium panels

| 1000 × 2000 mm | ||

|---|---|---|

| 0.6 mm | 1.0 mm | 2.0 mm |

| 3.2 kg | 5.4 kg | 10.8 kg |

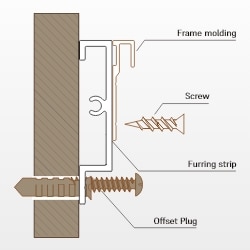

BASIC INSTALLATION METHODS - ALUMINIUM COMPOSITE BOARDS

Mounting Options and substructures

MOUNTING DIRECTLY ON THE WALL

If the surface is smooth and even, the aluminium composite panels can be mounted directly on the wall. For this, dowels, self-drilling screws, liquid adhesive, double-sided adhesive tape and a fastening strip are required.

USING THE FOUNDATION FRAMES

If the surface is not even, a foundation frame should be used. In this case, liquid adhesive, dowels, self-drilling screws, double-sided adhesive tape, fastening strips and an aluminium substructure are required for optimal fastening of the aluminium composite panels.

DIRECTLY ON AN INDEPENDENT FRAME

If the aluminium composite panels are to be fixed to a free-standing frame, for example as a room divider or privacy screen, the following materials are required for this – liquid adhesive, dowels, self-drilling screws, double-sided adhesive tape, fixing strip and a free-standing frame.

MATERIALS FOR INSTALLATION - ALUMINIUM COMPOSITE BOARDS

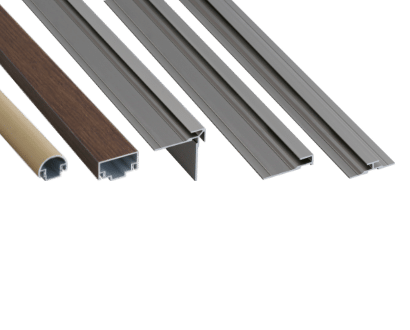

Bars and Rails for Molding and Frames

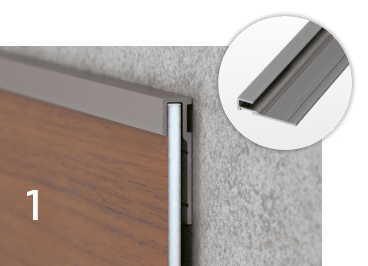

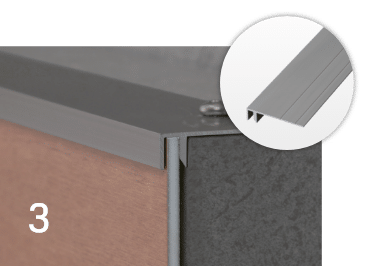

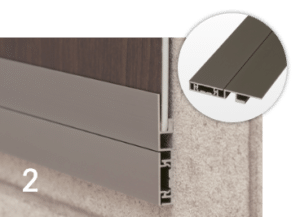

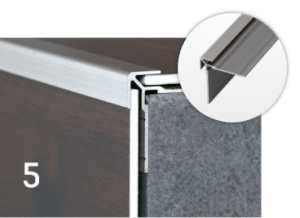

JOINT MOLDING FOR EVER ART BOARD®

Bars and rails

A variety of mouldings and rails enable an ideal connection between the individual composite panels (composite mouldings), optimal corner termination (corner composite moulding) as well as at the edge of the aluminium wall cladding (end moulding).

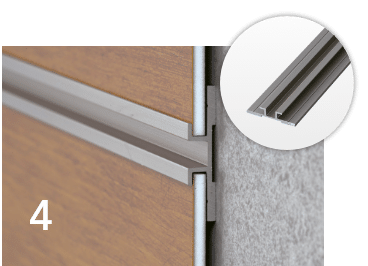

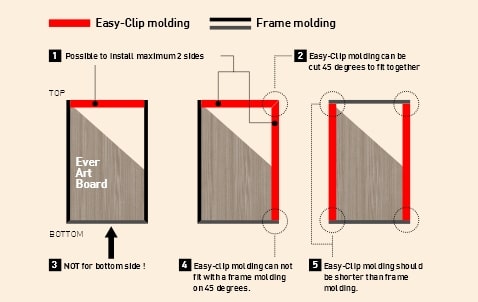

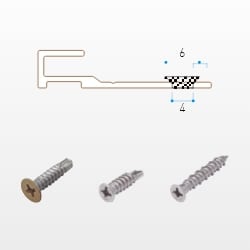

EASY CLIP MOLDING FOR EVER ART BOARD®

Quick Installation on smooth flat surfaces

A variety of mouldings and rails enable an ideal connection between the individual composite panels (composite mouldings), optimal corner termination (corner composite moulding) as well as at the edge of the aluminium wall cladding (end moulding).

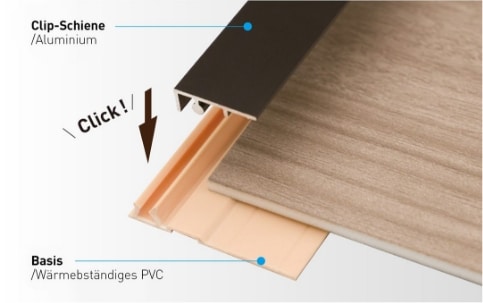

EASY CLIP RAIL

The clip rail helps with difficult work, such as at the edge of a ceiling panelling. The base of the clip rail is made of heat-resistant PVC and the clip cover strip is made of aluminium.

QUICK INSTALLATION

Clip rails can be used for quick installation. Here, the installation process involves only three steps. First, the clip base is installed, then the EVER ART BOARD is inserted and finally the clip cover strip is installed. The clip rails are available in different colour variations. This means that the rail can always be selected to match the board.

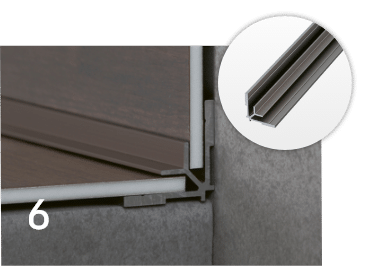

INSTALLATION METHOD FOR SMOOTH FLAT SURFACES

Clip rails and composite strips are used for installation on smooth and flat surfaces. Clip rails can be installed on two sides at the same time. A composite strip must be installed on the underside of EVER ART BOARD.

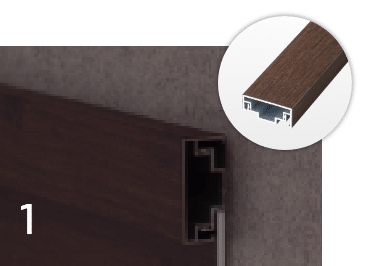

JOINT MOLDING FOR EVER ART BOARD®

Rails with texture

For more effects or a uniform look, rails with texture can be used. The textured surface finish gives the overall look more naturalness. You can achieve a high-contrast look by using different colours and brightness levels.

Frame center cover 22 × 15

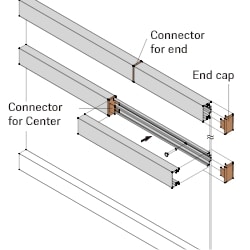

SQUARE FRAME FOR EVER ART BOARD®

Mounting on Posts

For more effects or a uniform look, rails with texture can be used. The textured surface finish gives the overall look more naturalness. You can achieve a high-contrast look by using different colours and brightness levels.

WALL CLADDING - ACCESSORIES FOR EVER ART BOARD®

Accessories

ALIUMINIUM COMPOSITE BOARDS - COLOURS AND DECORS

88 Design Options with EVER ART BOARD®

* = NATURAL TOUCH (EMBOSSING TEXTURE)

TAKASHO ALUMINIUM COMPOSITE BOARD SERIES

DESIGN PANELS

Unique accents for exterior spaces

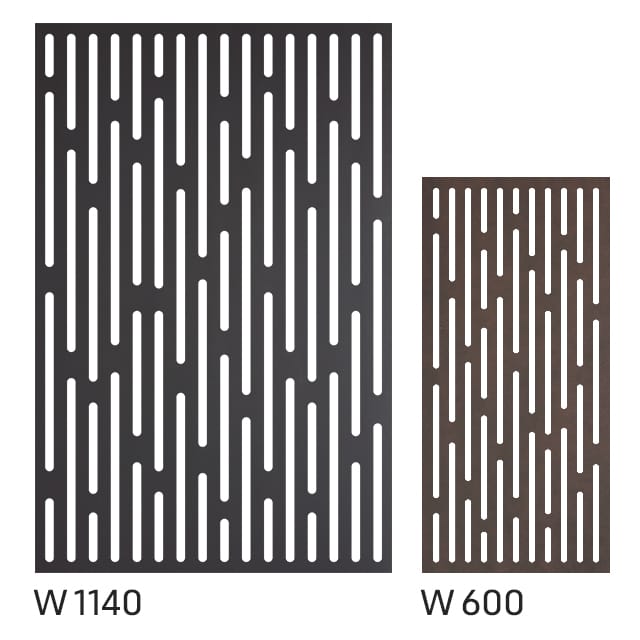

DESIGN PANELS - ALUMINIUM COMPOSITE BOARD

Unique accents with design panels

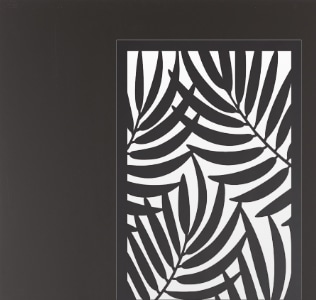

With aluminium design panels, you can realise emotionally appealing interior and exterior design with high visual value. The use of lighting techniques enables creative lighting design and creates a modern and cosy atmosphere with atmospheric accents. The high-quality workmanship of each design panel convinces with its stability and durability.

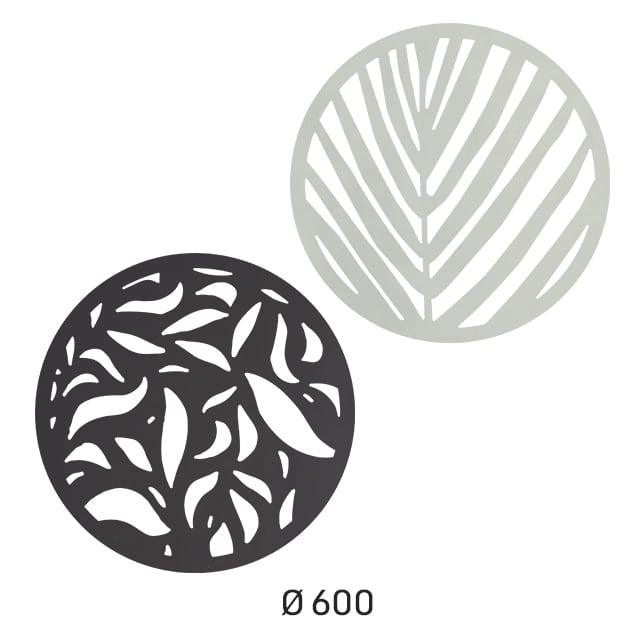

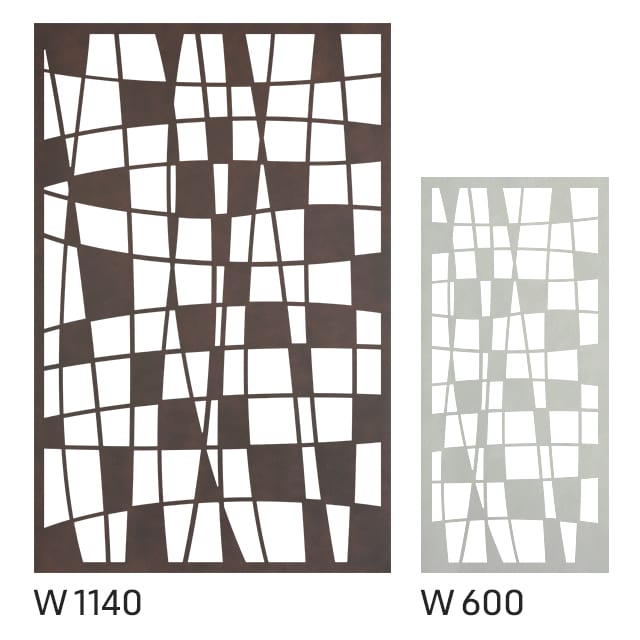

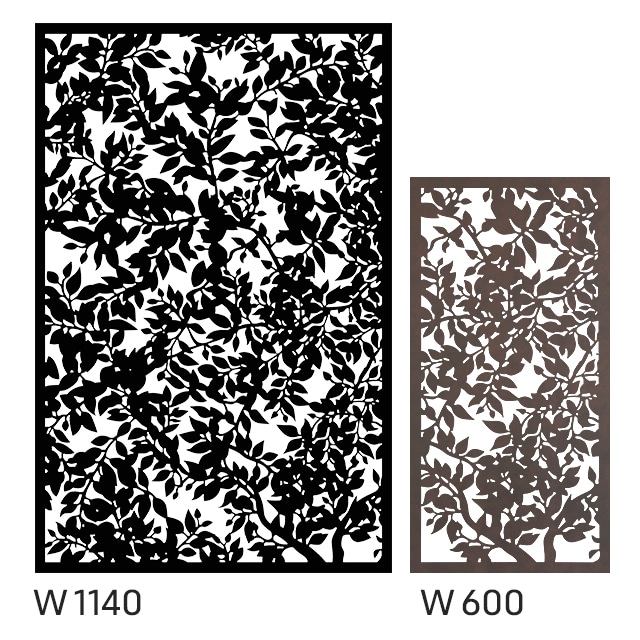

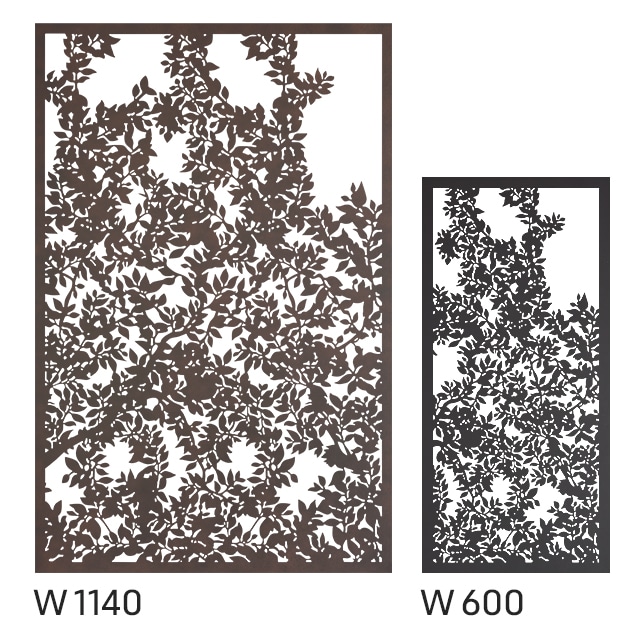

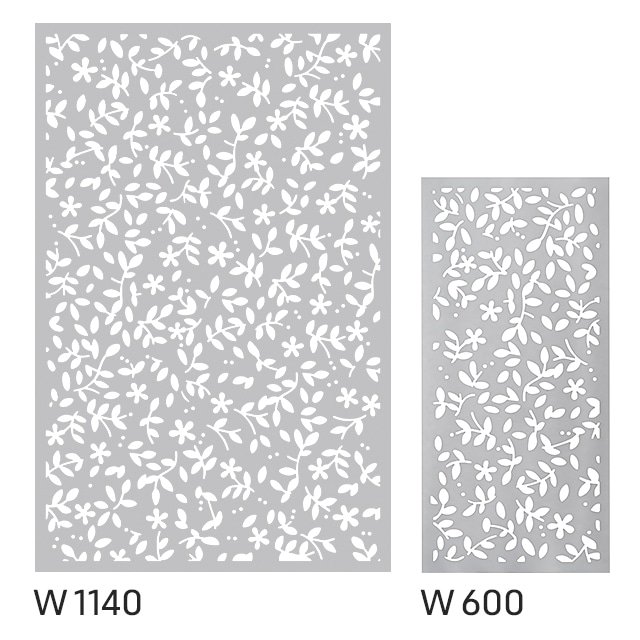

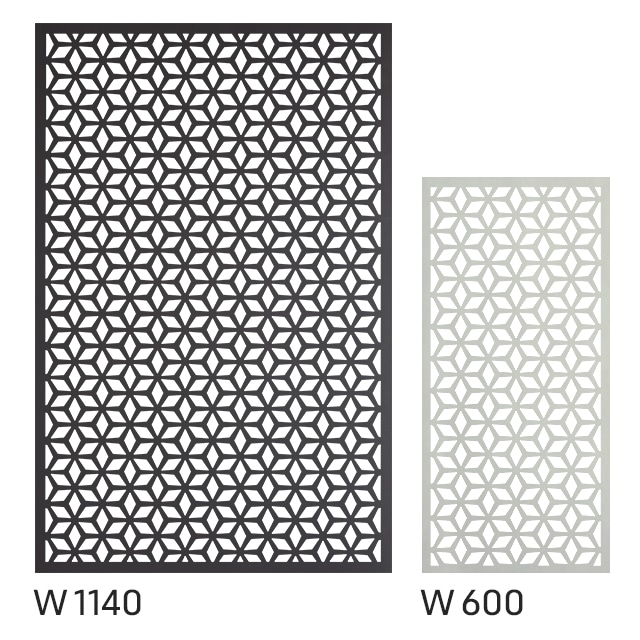

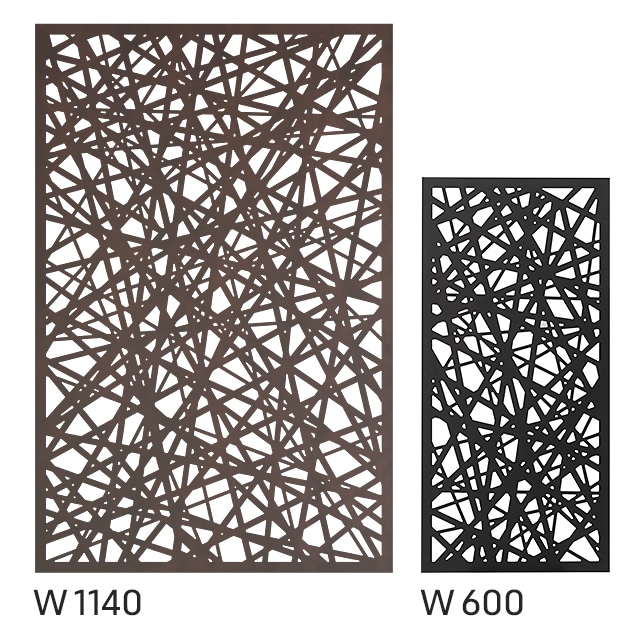

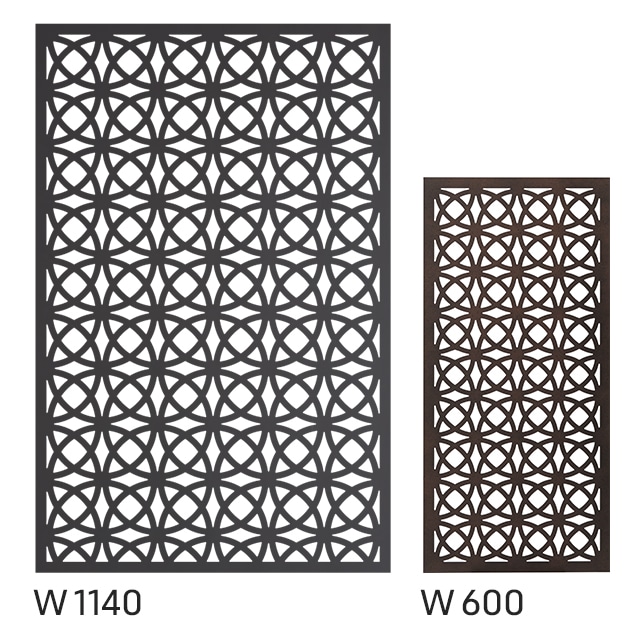

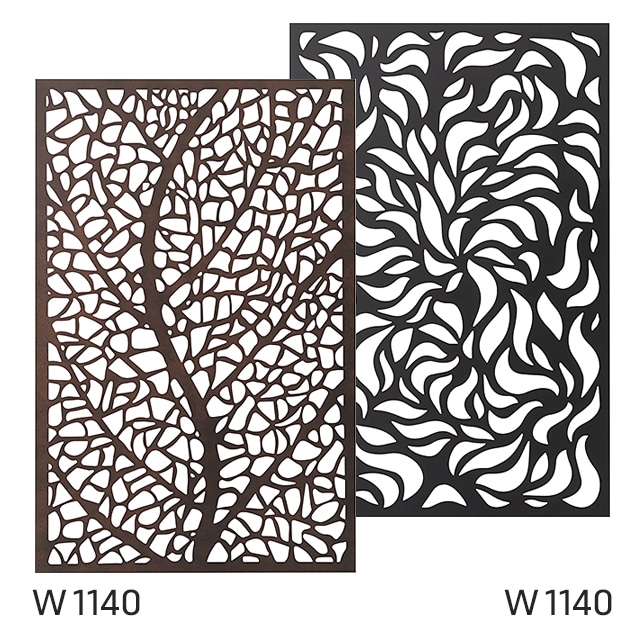

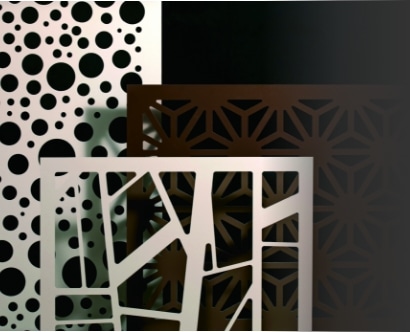

DESIGN PANELS - MOTIFS

Imaginative and individual motifs

Rooms and façades can be individually designed with imaginative motifs. The unique patterns, which are precisely cut into aluminium composite panels using laser technology, give the design an individual look. The design panel can either be free-standing or installed on a wall and gives your home special accents. Company logos also appear professional on the stylish design panels and offer a good opportunity for self-presentation.

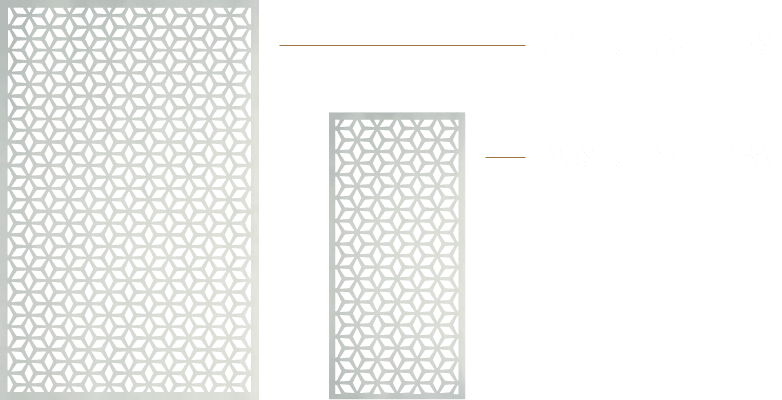

DESIGN PANELS - SIZES

Standard dimensions

The Design Panel is available in two standard sizes. The larger model (width 1140 x depth 3 x height 1760 cm) is ideal for large rooms or wall surfaces. In smaller rooms or gardens, the smaller version is more effective (width 600 x depth 3 x height 1265 cm). Despite the small depth, the panels convince with their stability.

DESIGN PANELS - COLOURS

Deliberate contrasts stylish effects

The Design Panel is available in three colours. The deep black (black) creates a stylish yet mysterious atmosphere that conveys independence and strength. Strong contrasts can be created by using the black colour. The light grey colour (shine) conveys lightness and light-heartedness. The light colour is often associated with purity, order and wisdom. The copper colour (copper) radiates a warm mood and immerses the rooms in a vintage look.

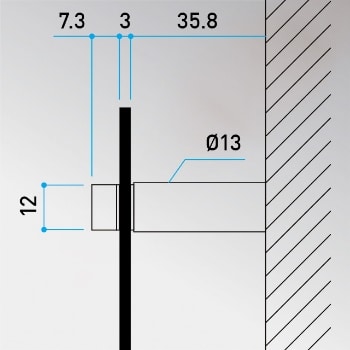

Screws and Spacers

| Panel Size | Quantity |

| Typ B 480: | 4 Pcs. |

| Typ B 600: | 4 Pcs. |

| Typ B 1140: | 10 Pcs. |

Mounting Sets

| Typ | Size in mm |

| 4 Pcs./Set | Ø 13 × H 43 mm |

| 6 Pcs./Set | Ø 13 × H 43 mm |

| Material: Stainless steel | |

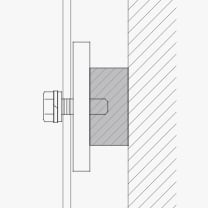

DESIGN PANELS - INSTALLATION

Easy installation with Assembly sets

The Design Panel is quick and easy to install. With our mounting sets, you can start right away. The spacers for fixing the panels can be purchased either as a 4-piece set or as a 6-piece set. Depending on the size of the Design Panel, different mounting sets are required. The sets differ in the number of screws. For panels with a width of 1140 cm, a set with 10 screws is required (type B1140). For smaller panel widths, sets with 4 screws are sufficient (type B480 and type B600).

MATERIALS FOR JAPANESE GARDEN DESIGN

EVER BAMBOO®

A perfect replica of natural bamboo.

JAPANESE GARDEN DESIGN - EVER BAMBOO PANELS AND MATERIALS

A perfect replica of natural bamboo

The look of the traditional Japanese bamboo plant combined with famous techniques of Kyoto craftsmen and qualitative, durable materials – that is EVER BAMBOO®. The attractive panels fascinate with their natural appearance and will transform your garden into a place of peace and relaxation.

Hand-painted as well as three-dimensional surfaces give a natural impression and the variety of colour shades presents the different bamboo varieties.

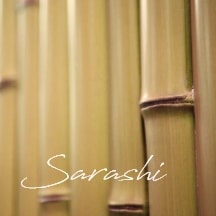

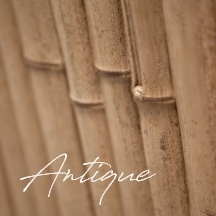

EVER BAMBOO - PANEL COLOURS AND PATTERNS

CLASSIC THEMES

With a wide range of traditional patterns, EVER BAMBOO® panels offer numerous design options for classic or also modern Japanese-style gardens.

EVER BAMBOO - PANEL COLOURS AND PATTERNS

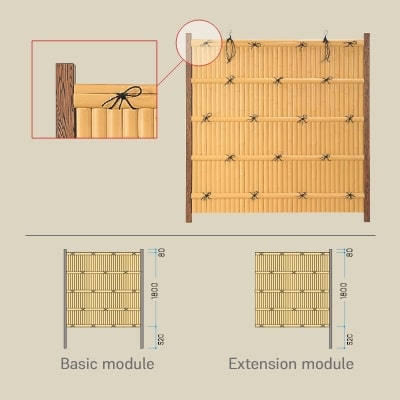

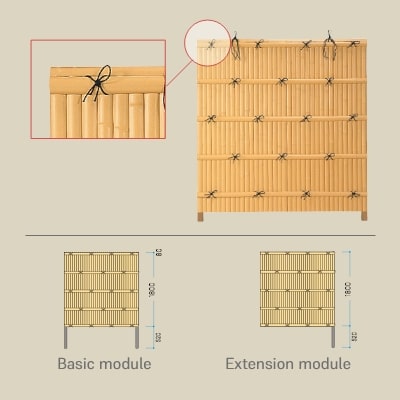

Extendable module system

Everything you need to build a bamboo fence is available in one set. Due to the modular system, you have two ordering options. For a free-standing fence element with two posts, select the “Basic” type. If you would like to extend your fence, select the “Extension” type. You can also choose between visible or concealed posts. Our experts will be happy to advise you.

JAPANESE GARDEN DESIGN - EVER BAMBOO PANELS AND MATERIALS

Natural colours and realistic surfaces

The variety of colour tones is faithfully made to match different types of bamboo. Surfaces aged by wind and weather can also be reproduced, as can bamboo that has been refined using traditional methods.

The bamboo structure is shaped with great attention to detail and precision, following nature’s example. Three-dimensional and hand-painted details create the special natural impression of the EVER BAMBOO® series.

MATERIALS FOR JAPANESE GARDEN DESIGN

ECO BAMBOO / DELUXE ARTISAN BAMBOO

A perfect replica of natural bamboo.

JAPANESE GARDEN DESIGN - EVER BAMBOO PANELS AND MATERIALS

A perfect replica of natural bamboo

The look of the traditional Japanese bamboo plant combined with famous techniques of Kyoto craftsmen and qualitative, durable materials – that is EVER BAMBOO®. The attractive panels fascinate with their natural appearance and will transform your garden into a place of peace and relaxation.

Hand-painted as well as three-dimensional surfaces give a natural impression and the variety of colour shades presents the different bamboo varieties.